BOM Manager

Hands down the best way to manage your ERP, item masters, BOMs and routings!

Productivity Matters

The “New Economy” has made your business leaner, but has it made you more productive.

Today’s business climate demands that you get the most out of all your resources. However, sometimes your ERP system gets in the way. You find highly paid Engineers, Project Managers and Customer Service personnel, dealing with mind-numbing tasks and forced to become data-entry clerks, just to feed the ERP “beast”.

Top 10 Features of the BOM Manager

Productivity is all about working smart and making the most of available resources. Progressive Edge designed the Bill of Material Manager (BOMM™) to relieve your Users of the menial tasks, which accompany Bill of Material management in your ERP system.

- Import both single and multi-level BOM’s from any Excel compatible source.

- Import and create Item Masters from any Excel compatible source.

- Item Master access and edit, controlled down to the field\column level.

- Embedded Routings.

- Compare BOM’s and Item Masters.

- Drag and Drop Editing (drag components from ANY BOM to any other BOM).

- Indented Where-used. (See where a component is used up to its top level).

- Works with ALL BOM Types (Standard, Job, Order and Quote).

- Indented Job BOM. (See the Job BOM in a product structure/indented view).

- Job Revision tracking. (Track all changes to the Job BOM with reason codes).

… all without using an ERP user license!!

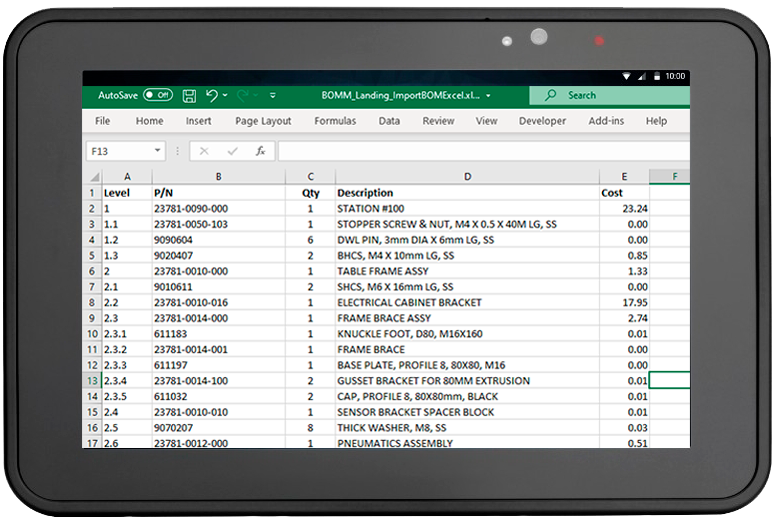

Import Capabilities

Outside of the BOMM™, your choices for Importing are a free tool that does not do much, or a paid tool that is very rigid, complex and expensive. The BOMM™ gives you the best choice: functionality and flexibility, at a great price point. Start with our Import Wizard, it is a function that walks you through the process of creating Maps from any Microsoft® Excel® compatible file. Imports can be previewed, appended, or replaced. You can import into any BOM type within your ERP System.

- Single and Multi-Level Import.

- Automatic Item Master creation (option).

- User-defined templates.

- Raw Material Assembly creation.

- User configurable Maps with preview.

- Automatic Sub-Assembly creation (option).

- Import “Preview” with Compare.

- Any Excel compatible file.

Item Master FlexView

Working with Bill of Materials obviously requires a tight interface with your Item Masters. We have included our Item FlexView™ at no additional charge. What is the Item FlexView™? It is a tool that provides controlled access to your Item Master data, with the ability to customize exactly what each user is presented. View, add or edit control for each element (field) in your Item Master.

In addition, users can view, edit and compare Item Master values side by side. You can compare all the revisions of a part, side by side. Or, if you use Multi-facility, you can compare a part across the different facilities it is in.

Drill-downs into detail data are provided at the click of a mouse.

- User specific control to View\Edit every element (field) on the Item Master.

- Add New Part from Existing (Copy).

- View\Compare\Edit multiple parts, side by side.

- Complete Operational Status per component.

- Accessible inside or outside the BOMM™.

- Ability to Master Control Part number creations and field values.

- User configurable “layouts” to see the Item Master elements in they order and groups they choose.

- Add New Part from Template.

- Drill-down into detail data like On Hand, On Order, etc.

- Incorporate “extension” columns.

Mass Change Capabilities

Does your ERP lack basic “Where-Used” and “Mass-Change” capabilities? Are customer changes, recalls, and revisions weeklong tasks?

The BOMM™ provides robust capabilities in both these areas. First, you may search with wild cards and more than one part at a time. Second, you can perform a component to top-level search. This will find the top-level parts which use the component at any level downstream.

In addition to replacing components, you also can add a new component and delete a component without having to replace an existing one.

- Search for one or more components at a time.

- Full search option to the Parent Parts.

- Search scopes by Effectivity, Customers, Document dates, Statuses, Group Codes and more.

- Adjust Component quantity when replacing.

- Where Used and Replace for ALL BOM Types (Standard, Job, Order and Quote).

- Optionally include\exclude Started and\or Obsolete Parents.

- Add and Delete components without needing to replace.

- Delete or Replace components can optionally Expire or Delete from BOM.

Drag and Drop Editing

Productivity is doing things with efficiency. The Drag and Drop functionality will become your best friend. You can drag components, assemblies and routings from ANY BOM to ANY other BOM, even if those BOM’s are of a different type (Job BOM to Sales Order BOM for example).

Easily select\deselect components and sub-assemblies to only include the structure you want to copy. Then just drag that selection into the BOM you are working on. No typing or errors. You can also select to drag the routings as well!

- Drag from any BOM Type to any BOM Type.

- Drag Routings. For example, a Job Routing to a Standard Routing.

- Reduces BOM creation time.

- Easily select the components and structure to drag.

- Preview and Error checking before saving.

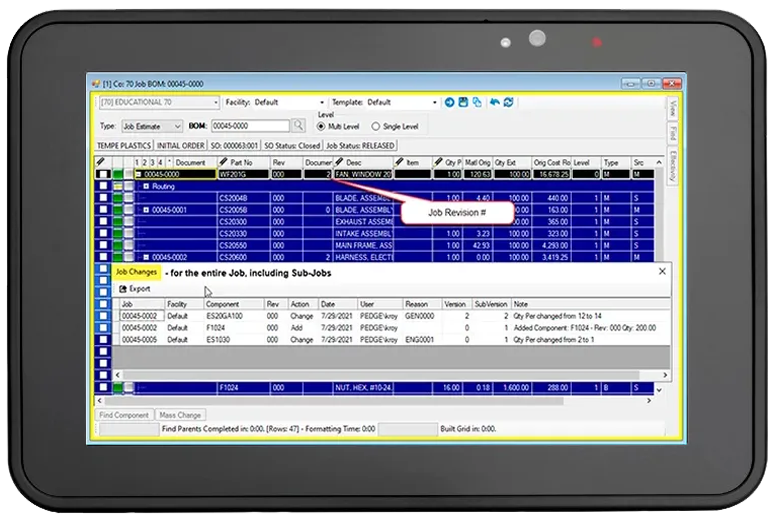

Job Revision Tracking

The BOMM™ allows you to track revisions to the Job BOM after the Job has been released. A change to a Released Job can require a Reason Code and force the “Job Revision” number to be sequenced. Elements tracked for each revision are: who made the change, the date, the reason code, the Job or sub-Job and the change being made.

Then revisions from any sub-Jobs are rolled up to the Parent, allowing full tracking to all levels of the Job. Revisions can be quickly exported to Excel®.

- User defined Reason Codes.

- Optional Revision code sequencing.

- Tracks who, when and why the revision was being made.

- Easily export to Excel®.

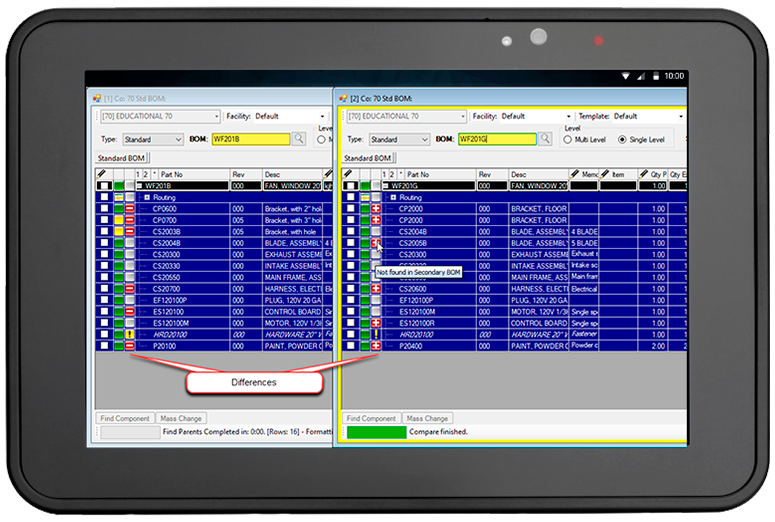

Compare BOMs

Quickly see the differences between any two BOMs in the system, even if they are of different types. Compare a Job BOM to its Standard BOM and have the difference highlighted. Import a BOM from Excel and compare it to the BOM you want to Import into.

- Identifies where components are different (exists in one and not the other).

- Compare before import.

- Identifies where the quantity is different (one BOM uses 25 another uses 100).

- Any BOM to any other BOM.